Wholesale Product Range

- CLIPPER BLADES ANDIS A5

- ANIMAL CLIPPER MACHINES

- MONK PURPLE SCISSORS

- WAHL SCISSORS

- ACCESSORIES / PARTS

Subscribe for Updates & Specials

Your clipper blades require some simple maintenance if they are to be successfully sharpened, and provide reliable working performance.

Consider Your Clipper Blades:

They are made from High Carbon Steel that rusts in the twinkle of an eye in damp and dirty conditions. So why use it? Carbon Steel is highly resistant to friction and holds an edge in the most trying conditions. Many of today's grooming machines sweep the cutter across the comb 4500 to 10,000 times per minute. It is not commonly known but Carbon steel has an ability to absorb oil, yes not much but some. Ever had an old blade that you kept oiling throughout its life, and as it got older it cut for longer and longer? That oil has been working into the steel from heat and friction.

Rusty blades have the opposite effect. The rust quickly works its way into the the metal, and it is often several grinds before it is completely gone. (Poor performance after sharpening? here might be some of the problem). I have to grind much more off a rusty blade than a well cared for blade to get to fresh steel and a reliable cutting surface.

Rust changes the nature of the carbon steel in a clipper blade, by oxidising it. The metal becomes weaker and more brittle. Pitting of the steel doesn't support an efficient, long lasting edge. Clipper blades love oil and hate moisture. You know how much you hate to see a dog matted to the skin? Well that how I feel about rust.

The basics:

(1) Brushing

Purchase a wirebrush from a hardware shop (brass for hairdressers). Brush the comb and cutter teeth free of all that dander that lodges in between the teeth. Don't worry that you are going to blunt a blade with a wire brush, your blade is carbon steel and far harder than the wire brush bristles. I have sharpened many blades that were not blunt, but had so much dander in the teeth that it would no longer pick up the hair to feed the cutter, hence the groomer considered them blunt. Dander in the clipper teeth breeds bacteria encourages rust, and increases comb drag.

(2) Oiling

Get some quality clipper blade oil. I will recommend Feather Edge Sharpening oil because it is solvent free and won't stain the human/animal coat. Never ever use vegetable oil. Natural oils oxidise to the point that they glue the cutter to the comb, and fill the teeth with gum often rendering the blade useless.

Oil the blade before you start and during the job. A tiny amount is all that's needed, you don't want the oil to bleed into the comb and get in the hair. Oil when the clipper blade is running, and blot with a rag once it is oiled.

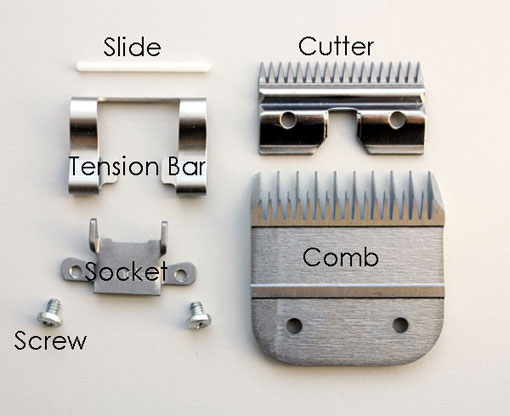

Oil with the machine running and the cutter will work the oil out towards the edges of the blade. This is why a small amount of oil goes a long way. The plastic slide on the tension bar should never be dry.

(3) Cleaning

Cleaning is the area where there is much urban myth. The advent of blade sprays and washes has lead to new marketable products with little benefit. Most are a chemical cocktail of solvents, glycol and aromatic chemicals to enhance the nature of the product. Any product that contains solvent has the potential to get into the clipper. A clipper vibrates during normal operation, so solvent easily works it's way into the gearbox. Excellerated gearbox wear is a potential problem, as bearings and gears are stripped of lubrication and degenerate faster. One part of the clipper that should be stricly dry is the motor. I have seen blade wash get into motors causing them to fail completely.

The old recipie that you use a 50/50 kerosine/oil mix, and dip the head of the machine into it, was started in the 1960's by a major horseclipper maufacturer and still has proponents today. Never use kerosine. It increases friction of metal surfaces, and wears clipper parts out faster than almost anything I have ever seen.

Some have tried ultrasonic cleaners and autoclaves, They both require heat and water, this strips lubrication and invites rust straight away. Incorrectly used; ultrasonic cleaners can lift the plated surfaces off the clipper blade, weakening the metal parts.

The Only Thing I suggest You Use is Methylated Sprits or Denatured Alcohol. So Why?

1. Alcohol is hygroscopic (sucks up water) so clipper blade moisture is dissolved.

2. Non toxic to the user unless you take a fancy to having a swig of it

3. It evaporates quickly without residue and is unable to get into the clipping machine

4. Very cheap from the hardware store and easily available.

5. Is not aggressive enough to strip the oil from the blade over a short time

6. Sterilises whatever it contacts

The Main Points to Remember:

Corrosion takes place in the presence of water or blood. In order to minimise the harmful effects of corrosion; lube the blades with clear oil while the clippers are running. Remember rust starts work when you stop.

Dirt and grit on the coats of animals will increase clipper wear. Whilst it is not always practical to wash and dry every animal, top Groomers are able to clip many more clean dogs than dirty ones before blade sharpening. Modern high speed clippers allow Groomers many more dirty clips than was once possible.

Lubrication In contrast with sheep's wool, which contains a large amount of oil, most other animal hair is dry. For best results the blades should be oiled every 10-15 minutes with light clear oil such as Feather Edge clipper oil. Do not use a 3-in-1 oil, i.e. WD40 or vegetable oil, as these will leave a sticky residue after the volatile constituents have evaporated. Never use a mix of kerosene and oil to lubricate your blades (an urban myth from the 1960's), this combination destroys clipper gearboxes, and decreases blade life.

The primary reason that people complain that their clipper blades don't last long, is because they allow them to run dry during use.

Overheating Friction between the comb and cutter causes heat during use. During use, the hair and contact carry the heat away from the animals skin. Do not run the clipper blades for long periods unless they are clipping hair. Regular blade oiling also minimises blade temperature.

Clogging of the comb and cutter can occur from dander and other substances. Finer blades have a particular problem in this area, and may result in them being prematurely discarded. Cleaning with a wire brush all dander from the cutter and comb will enable further use before resharpening. Always ensure your blades are dry, (possibly from a warm drier) and oil to prevent corrosion.

Blunt blades should be wire brushed clean, and stored in a dry place prior to being put aside for sharpening. The result of tossing the blades aside encourages corrosion that needs to be machined out, and reduces the number of times they may be sharpened. Store blunt blades in a dry caddie such as the Blunt Blade Box

Your cart is empty!

Your cart is empty!